Pure Nordic Distillery as the name says is about purity. We also wanted to bring out that ecological way of doing is one of our advantage also.

Purity : Mainly we have used the following processes

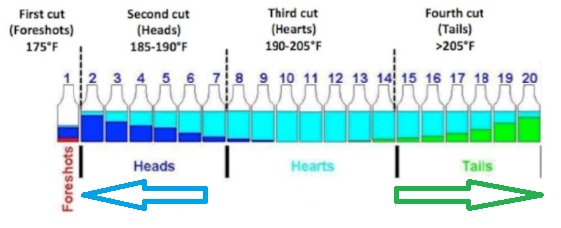

- Best possible distilling portion is taken into use only.

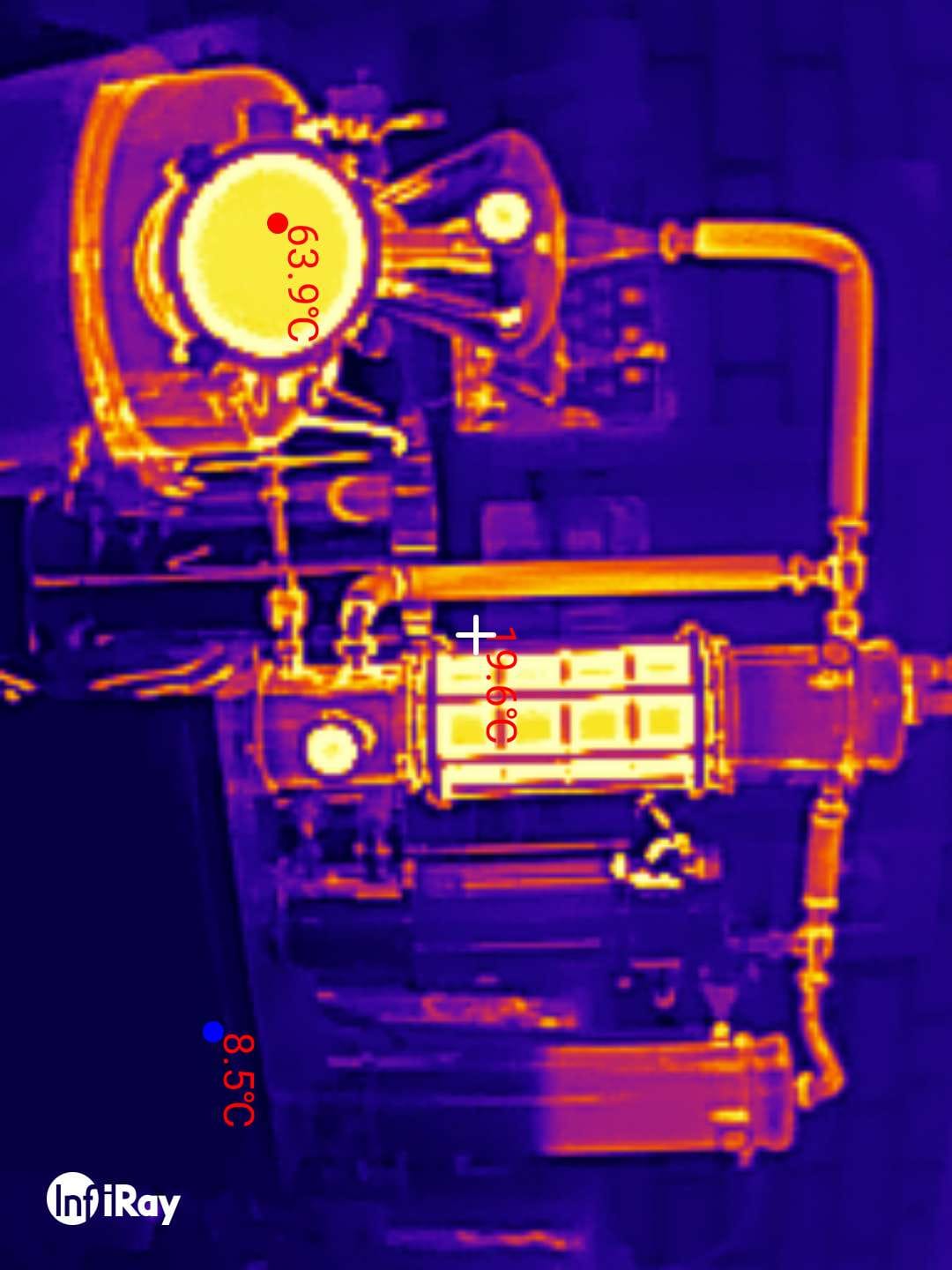

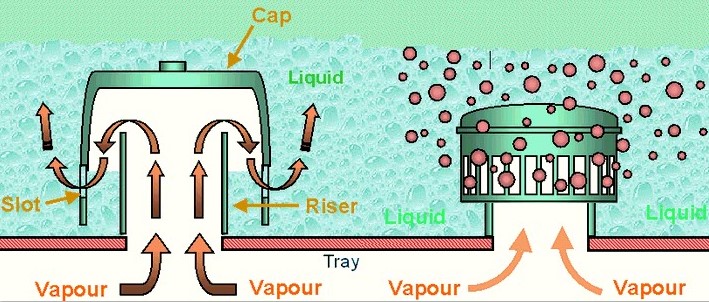

We Only use the non-toxic parts of distilling. - 5 times re-distilling - Our machine pre distills in union head with turbulent usage of vapour, then our distilling bubble plates are larger than normal giving even output without any push from distiller.

- Counter-pressure filtering → extremely efficient and high grade filtering -> This is slow process, to give enough time for active coal to be actually active in filtering we have developed counter pressure filtering.

- Reverse Osmosis water = Extra filtered water, water is almost same as distilled water, will not give any extra taste or division between ethanol or water.

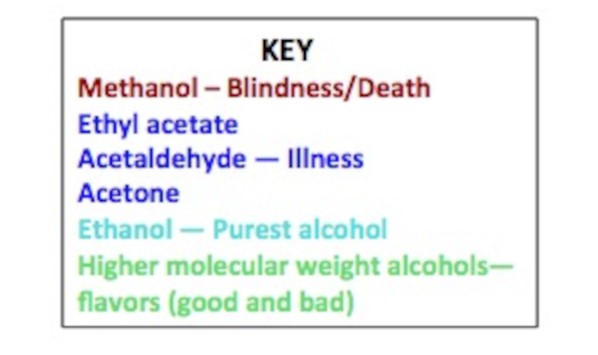

We use only Finnish Altia grain based ethanol as our main baseline. -> This is already purest baselines there is.Its from Finnish grain only and using grain only gives one of the most cleanest products considering extra parts created in the distilling process.

Any fluctuation or other increadients increase the methanol and other incredients amount.

This way using the purest baseline it gives purest output

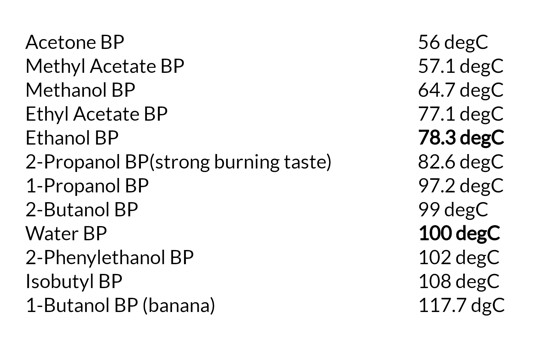

In Normal distilling process with normal mostly used machines the whole process is delivering alot of chemicals other than ethanol which here is described as "hearts". Pure Nordic Distillery machine is designed to be accurate thermal managements (0.1degrees possible temperature setting) where we can prevent "hearts" start and prevent overheating"tails"

Eg. preventing ethanol temperature the "heads" part can be forced out before any ethanol taken out. Same applies for over 78.3 ethanol chemicals coming afterwards as "tails)

Ecological

Since out machine can control temperature :

* we are not forces to push distilling fast forward and focus on delivering accurate and pure ethanol.

* Since we dont push we dont need to run cooling water extensively to keep the Propanol/butanol/water to be introduced extensively to final product.

* It has been estimated that we use 1/10th of cooling water normally used in normal distilling machines

* it has been estimated that our machine is consuming electricity only portion what normal machine is using (due normal machine is always on)

* The cooling water used per batch size of 200-250litres is consuming water ~500-800litres

(when normal machine might consume 4-6cubic meters (4000-6000litres) of cooling water)